Guidelines and Application Procedures

for API RP 578

Positive Material Identification using XRF, OES, & LIBS Technologies

Guidelines and Application Procedures for

API RP 578 Positive Material Identification

| Class Dates | ||

|---|---|---|

| February 14-15, 2024 | $1,350 API Member | $1,850 Non-Member |

| April 10-11, 2024 | $1,350 API Member | $1,850 Non-Member |

| June 19-20, 2024 | $1,350 API Member | $1,850 Non-Member |

| August 14-15, 2024 | $1,350 API Member | $1,850 Non-Member |

| October 16-17, 2024 | $1,350 API Member | $1,850 Non-Member |

| December 4-5, 2024 | $1,350 API Member | $1,850 Non-Member |

Learning Objectives

- Understand and apply API Recommended Practice 578 Positive Material Identification (PMI) Guidelines.

- Explain How OSHA Instruction-CLP 03-00-004 Nation Emphasis Program (NEP) Applies to Their Industry.

- Better Understanding of OSHA CPL-02-02-045. Process Safety Management (PSM) 29CFR1910.119 With Proper Material Verification Program and Training.

- Practical PMI Applications Using XRF/OES & LIBS Technologies.

- Technical Understanding of How XRF Technology Works.

- Technical Understanding of How OES & LIBS Technology Works.

- Recognize Safe Practices Utilizing XRF Technology. Radiation Safety Understanding How “As Low As Reasonably Achievable” (ALARA) can be Attained.

- Applying “Recognized And Generally Accepted Good Engineering Practices”(RAGAGEP) for Inspection of Material, Warehouse Material Identification Through Positive Material Identification PMI XRF/OES/LIBS Analysis.

Course Agenda

Day 1

- Introduction

- Instructor background

- API 578 3rd edition overview

- OSHA National Emphasis Program (NEP)

- Importance of a Material Verification Program (MVP)

- Bibliography Definitions Acronyms

- API 578 normative references

- Common definitions

- Review industry acronyms

- Statistical Terminology

- Review & apply statistical terms (accuracy, precision, bias)

- Understanding types of error and 2-sigma confidence (95%)

- Limit of detection (LOD) vs. limit of quantification (LOQ)

- Effects of measurement time

- XRF Technology

- Principle operation of XRF, radioisotopes vs. x-ray tubes

- Empirical vs. fundamental parameters calibration

- Detector types (Si-PIN & SDD), light element detection

- Instructor live demonstration

- Radiation Safety

- ALARA (As Low as Reasonably Achievable)

- Time, distance, shielding & safe analysis guidelines

- Primary & secondary radiation review

- Licensing, utilization & dose limits

- LIBS Technology

- Principle operation of LIBS, laser safety, routine maintenance

- Typical performance data, elements of interest, carbon limits

- Wavelength vs. drift correction vs. type standardization

- Instructor live demonstration

- OES Technology

- Principle operation of OES, routine maintenance

- Typical performance data, common applications

- OES vs. LIBS comparison

- Video demonstration

- Sample Preparation

- Component selection (grinder, pads, discs)

- Standardizing the preparation process

- Identifying acceptable preparation locations

- Results of poor sample preparation technique

- Stainless Steels

- Importance of individual elements

- Categories of stainless steels

- Carbon content, L&H grade applications

- Intergranular corrosion (IGC), creep, weld decay

- Carbon & Low Alloy Steels

- Importance of individual elements

- Classifications of steels

- Review & role of micro alloys

- Analyzer selection for key applications

- Carbon Equivalency (CE)

- Importance of carbon equivalency

- Review of equations (IIW, AWS, Pcm)

- Applications requiring carbon equivalency

- Analyzer selection & technical limits

Day 2

- Sulfidation Corrosion

- Mechanism overview (API 939-C)

- Thresholds & elements of interest (Si)

- Analyzer selection & technical limits

- Selection of certified reference materials (CRM’s)

- HF Alkylation Residual Elements

- Mechanism overview (API 751)

- Equations & elements of interest (C, Cu, Ni, Cr, Nb, V)

- Analyzer selection & technical limits

- Selection of certified reference materials (CRM’s)

- PHMSA Mega Rule

- Regulatory overview & timeline

- Traceable, Verifiable, Complete (TVC)

- Material verification techniques

- Review of API 5L line pipe chemistry

- PMI of Welds

- Weld types (GTAW, SMAW, GMAW, FCAW)

- Importance of testing weld metal prior to fabrication

- Contamination of welds through buffing, cleaning, wire wheels

- Weld metal chemistry vs. base metal chemistry

- Weld Dilution

- Conceptual understanding with qualitative analysis

- Analyzer grade library (ID mode) vs. ASTM Section II

- Weld selection for common alloys

- Practical review (hands-on)

- Marking Color Coding Reporting

- Methods for identifying tested material

- Documenting PMI test results with 100% traceability

- Color coding & acceptable methods

- Using analyzer features for storing relevant data

- XRF vs. LIBS Comparison

- Key applications for each method

- Limitations and analyzer selection

- Differences in sample preparation

- Elements detectable by XRF & LIBS

- Basic Alloy Chemistry

- Review of Basic 8 alloys (stainless & Cr-Mo)

- ASTM/ASME Section II-A, B, C acceptance criteria

- Chemistry differences between product forms (cast, plate, weld, etc.)

- Separating ID from the assay, commitment to memorization

- Hands-On XRF/LIBS Lab

- Review & Test

Day 3 (Optional)

Application Specific per customer request

Who should attend the course?

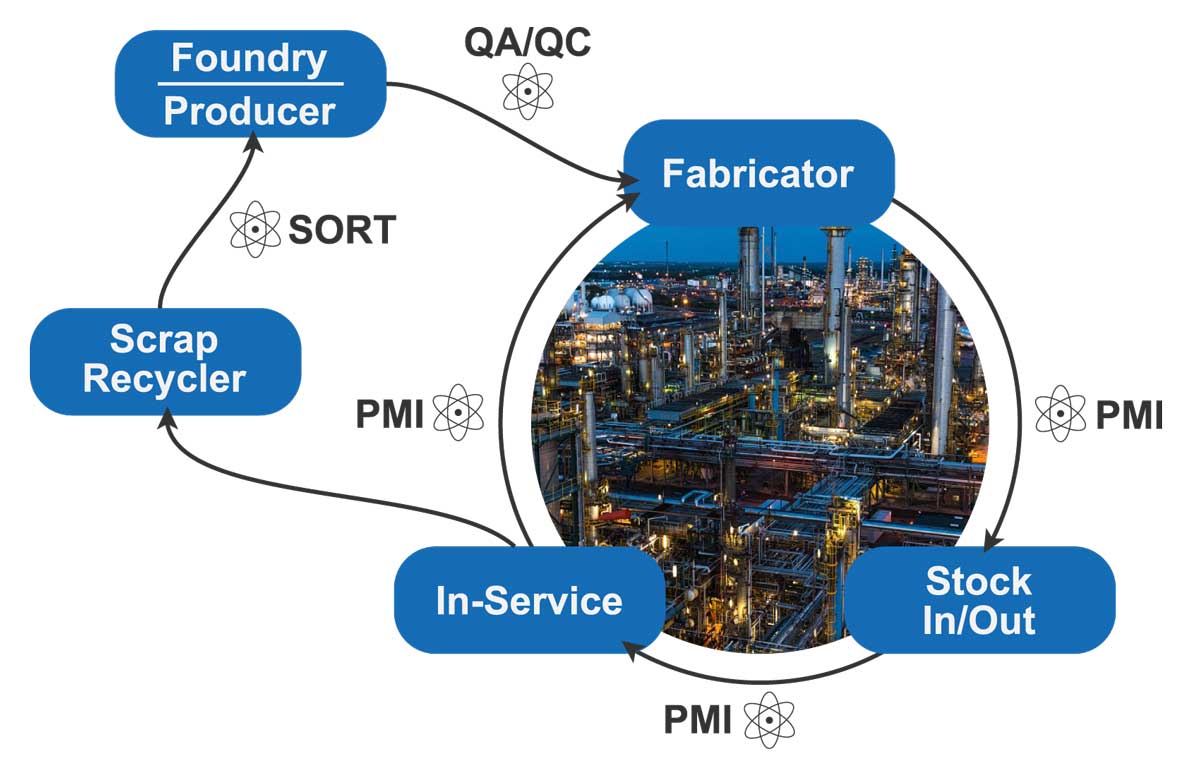

Analytical Training Consultants believes that Material Verification and PMI is now industry driven and nearly 100% required, so we have gone through the requirements of the API/TPCP ( stated above ) to provide you with the API RP 578 PMI Certification. As the graphic for the “PMI Process “below indicates : all groups from the foundry/producer to fabrication, warehouse, in service process, to scrap recycling, require Proper PMI analysis. Anyone and everyone involved with any of these processes need to be properly trained to perform qualified Material Verification through the use of XRF and OES/LIBS technologies. The Positive Material Identification (PMI) analysis is the only way to give assurance that the proper alloy is being used and will work according to design criteria.

All students enrolled in API 510, 570 classes, QA/QC inspectors, maintenance, stores, warehouse, inspection testing companies, fabrication shop, and reliability departments for oil and gas (Petrochemical and Refining) operations.

Why should the course be given?

PHMSA-Gas P/L Mega Rule

PHMSA proposed criteria that would require material properties verification for higher-risk locations through a new § 192.607; specifically, by adding requirements for the verification of pipeline material properties for existing onshore, steel, gas transmission pipelines that are located in HCAs or Class 3 or Class 4 locations.

The PHMSA Rules & Reg. Mega Rule 49 CFR 191 $196 Hi-Lited for MVP 1-30-2020 can be found here. I have Hi-Lited the important parts out of the 78 pages, ( starts on page 11 & 13 for Material Verification ) for the reader to get informed.

Material Chemistry Verification” for Pipeline Sector using XRF Technology. PMI seminar TransCanada by Don Mears on 7/9/2014.

September 9 thru 13 API organized the first API Beijing Conference. Don Mears was asked to present the API RP 578 (PMI) Program.

On March 6, 2012, Don Mears presented below speech on Positive Material Identification (PMI) at the first API Singapore Conference.

OSHA INSTRUCTION: Directive number CPL 03-00-004, effective June 7, 2007, which is the “Petroleum Refinery Process Safety Management Emphasis Program”.

“This instruction describes policies and procedures for implementing a National Emphasis Program (NEP) to reduce or eliminate the workplace hazards associated with the catastrophic release of highly hazardous chemicals at petroleum refineries”.

Don Mears gave a speech at the API Inspector Summit, held in Galveston (TX), January 27-30, 2009 (click here to download this API summit speech) .

Executive Summary Chem NEP-2017 CPL 03-00-021

This instruction provides guidance to the Occupational Safety and Health Administration’s (OSHA’s) national, regional, area, and State Plan offices for implementing and conducting an NEP to reduce or eliminate workplace hazards associated with the catastrophic release of highly hazardous chemicals at facilities, including petroleum refineries, covered by OSHA’s Process Safety Management of Highly Hazardous Chemicals (PSM) standard, 29 CFR 1910.119. Both programmed and un-programmed inspections associated with this NEP will begin immediately in all regions.

Significant Changes

This instruction describes an updated initiative by OSHA. Under the previous related instructions, OSHA conducted inspections of facilities covered by OSHA’s PSM standard either through an instruction specific to petroleum refineries or an instruction related to all other PSM-covered chemical facilities excluding petroleum refineries. This instruction is applicable to all facilities, including petroleum refineries, covered by the PSM standard. NEP inspections conducted at petroleum refineries will be conducted in the same manner as NEP inspections conducted at all other facilities covered by this instruction.

Safety Bulletin from U.S. Chemical Safety and Hazard Investigation Board (CSB)—BP Texas City

On July 28, 2005, 4 months after a devastating incident in the Isomerization (Isom) Unit that killed 15 workers and injured 180, the BP Texas City refinery experienced a major fire in the Resid Hydrotreater Unit (RHU) that caused a reported $30 million in property damage. One employee sustained a minor injury during the emergency unit shutdown and there were no fatalities.

Safety Bulletin from U.S. Chemical Safety and Hazard Investigation Board (CSB) —Chlorine Transfer Hose Failure

Chlorine Transfer Hose Failure due to improper material braid construction (i.e., 316L and not the recommended braid of Hastelloy C-276). On August 14, 2002 a 1- inch transfer line ruptured during a railcar offloading operation at DPC Enterprises in Festus, Missouri and released 48,000 pounds of Chlorine into neighboring areas.

All the Reported and Unreported “Near Misses” the Oil and Gas Industry has Experienced.

Many give examples of this or have witnessed this happening. Because of either Luck, Proper PMI / Inspection, Training, or Recognized and Generally Accepted Good Engineering Practices (RAGAGEP) (i.e. API RP 578), we were able to apply these principles and stop the “Near Misses” from turning into catastrophe.