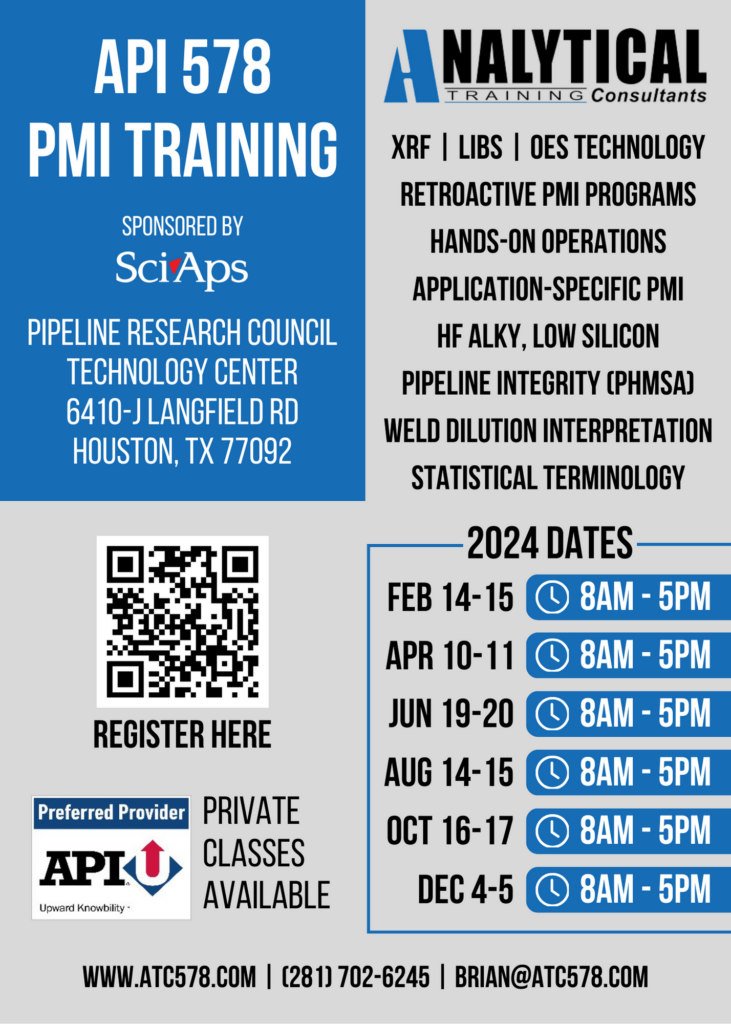

API 578 Training Provider

Guidelines and Application Procedures for API RP 578 Positive Material Identification (PMI) Using XRF/OES/LIBS Technologies

The course is covered in 2-day sessions of instruction on both classroom theory and field testing procedures through:

- Understanding API RP 578 Guidelines

- Application of Proper PMI Testing Procedures

XRF X-Ray Fluorescence

OES Optical Emission Spectroscopy

LIBS Laser Induced Breakdown Spectroscopy